Service Agreements

Find out more about our Service Agreements here.

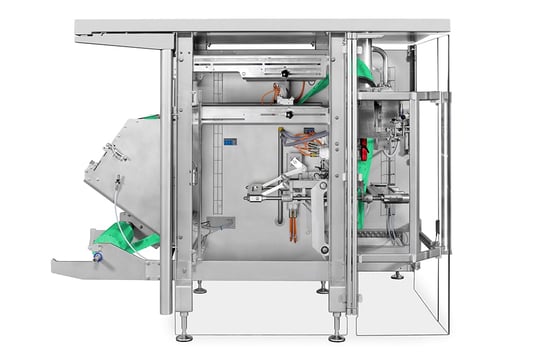

Vertical packaging has been around for many decades and has established itself as a standard for a wide range of food and non-food products. As consumer and market requirements are constantly evolving, we keep on innovating our trusted VFFS packaging machine. From sustainable packaging material to greater flexibility in bag styles increased output and hygienic operations, we deliver state-of-the-art packaging equipment.

Whether you are looking for a high-speed solution for stick packs, vacuum packing of coffee, or want your products to stand out at the point of sale with stand-up reclosable Doy Zip bags – our vffs machine portfolio helps you optimize your packaging process.

The new SVX-series features a patent pending cross seal drive, providing the highest speeds in the industry. With an intuitive user interface plus a footprint so small, the SVX integrates seamlessly into new and existing packaging lines.

Omnitrade, a family business specialized in sourcing, processing, finishing, and commissioning of nuts and dried fruit, has excelled globally in the retail and food industries. For over 14 years, their partnership with Syntegon has ensured excellent, cutting-edge packaging solutions.

Our intuitive HMI allows easy operation and a short training time. Its user-centric design ensures that the operator only sees applicable settings, making it easier to control the system and reduce errors.

Thanks to its user-guided workflow, our HMI further reduces changeover times and enables easy recipe set-up.

All our vertical form fill seal machines have been built to ensure robust processes. The maintenance-free servo-technology and continuous motion of our VFFS machine series help you not only achieve a precise and smooth production, but also high-quality bags.

Our VFFS machine series have a modern design and are adapted to the needs of your product and packaging environment. The SVC is the most hygienic machine of our portfolio. It is suitable for harsh production environments and easy washdown cleaning, keeping your consumers safe and protecting your brand from expensive product recalls.

Quick changes between different formats and bag styles are key to maintain flexible production on a single vertical form fill seal machine and optimize output. Our machines help you achieve that flexibility with fast and easy changeovers that keep your machine downtime to a strict minimum. Our SVE Doy Zip VFFS bagger, for instance, makes it possible to change from pillow to Doy Zip in as little as 30 minutes.

Our sealing technology with a seal force of up to 8 kN makes for high-quality seals. The solutions help you meet your industry, pack style, and material needs with ease. For the frozen food industry in particular, we developed the PHS sealing system, enabling a higher output while reducing the required packaging material per bag.

In case you want to produce Doy Zip bags with outstanding quality, we have a patented zipper application and long-seal technology in store. With its straight-edged lines and airtight seals, this packaging style gives brands an exceptional look and feel.

Our VFFS packaging machine portfolio stands for maximum flexibility. Make your choice depending on the bag styles you require now and in the future – you can rest assured we have what your are looking for, including several options for top closures. You can further keep your product fresh and improve consumer convenience with a reclosable zip or tape.

When it comes to vertical intermittent motion, our portfolio offers an economic range of solutions that cater to basic bag styles and moderate machine output.

Food producers often approach us to find a sustainable packaging solution. We can offer comprehensive support: we have already developed systems for a variety of industries such as frozen food, coffee, confectionery, dry pasta, powder and snacks. Depending on your product’s unique characteristics we determine the right sustainable concept. With our guidance and full service offer, you can be sure to bring your goods to market successfully.

Partnering for sustainable packaging solutions

Chocolate manufacturer Ritter Sport and Syntegon develop sustainable paper packaging.

Soul Food – Packed in Paper

ALB-GOLD Teigwaren is the first pasta producer in Germany to present its short pasta in sealed paper packaging.

Wolf Nudeln uses paper instead of plastic

Novel sealed paper packaging by BillerudKorsnäs and Syntegon for premium pasta.

Find out more about our Service Agreements here.

Find out more about Digital Solutions here.

Find out more about Parts here.

Find out more about Maintenance here.

/remote-assistant.jpg?width=640&height=380&name=remote-assistant.jpg)

Find out more about Technical Support here.

Find out more about Modernizations here.

Find out more about our Training here.

Find out more about our Expert Services here.

The future of vertical packaging

Explore our continuous motion bagger portfolio

Explore our hygienic continuous motion baggers

/soft-packing-bags.jpg?width=270&height=152&name=soft-packing-bags.jpg)

Highest flexibility through modular design

/PMX_4001_Front.jpg?width=270&height=152&name=PMX_4001_Front.jpg)

Compact. Sustainable. Future-proof.

Learn more about our sustainable coffee packaging solutions.

Uncover the secret to visually stunning biscuits, cookies, and crackers. Our site highlights the...

Learn how Syntegon empowers cookie and cracker producers to navigate industry challenges, including...

Discover the features of every biscuit, cookie, and cracker. From shapes to fillings, our expertise...

Discover innovative confectionery solutions at ProSweets 2025, booth D045, Hall 10.1. Experience...

Vertical packaging, also known as vertical form fill seal (VFFS) packaging, is a method used in the packaging industry to create sealed bags or pouches from a flat roll of packaging material. The process involves forming a vertical tube or cylinder from the packaging material, filling it with the product from the top by gravity, and then sealing the bag to create individual packages. This method is widely used for packaging various types of products, including food items, pharmaceuticals, and other consumer goods.

Vertical packaging equipment can be used to pack a wide variety of products such as snacks, confectionery, grains and cereals, bakery products, frozen food, powdered products, pet food, pharmaceuticals, detergents, coffee and tea, cheese and many more.

Every product has its characteristics. This creates specific requirements from the packaging material and the vertical form fill seal machine to keep the product both fresh and safe.

Which type of vertical form fill seal machine is right for you depends on several factors such as your product, required bag styles, bag size, output of the machine, etc.

Continuous motion vertical machine: these machines operate continuously without stopping between packaging cycles, leading to higher production speeds and efficiency. They are often used in high-volume production lines.

Intermittent motion vertical machine: in contrast to continuous motion machines, intermittent motion machines stop between each packaging cycle. They are suitable for various products and are a good fit when the volume per bag is high and/or the output in bags per minute is less important.

Vertical sachet machine: these machines are specialized for producing small, single-use sachets. They are commonly used for packaging products such as sugar, salt, ketchup, and instant coffee.

Vertical stick pack machine: stick pack machines are designed to create slim, elongated packages, often used for single-serve portions of products like sugar, instant coffee, and pharmaceutical powders.

Choosing the right vertical packaging machine for your specific packaging needs involves considering various factors to ensure that the machine aligns with your production requirements, product characteristics, and industry standards. Here's a guide to help you make an informed decision:

Type of product: consider the nature of your product (solid, liquid, powder, granular) and its specific characteristics (e.g. size, shape, fragility, stickiness). Different vertical form fill seal machines are designed for various product types.

Packaging material: identify the type of packaging material you intend to use (e.g. mono material, laminates, paper) and ensure that the chosen machine is compatible with it. And make sure the machine can run both the materials you intend to use now on the machine as well as potentially more sustainable options in the future.

Packaging format: determine the desired packaging format, including bag size, shape, and style. Some vertical packaging machines are versatile and can handle different formats, while others are designed for specific configurations (e.g. pillow bags, gusseted bags, stick packs, doy).

Production volume: assess your production requirements in terms of the output in bags/packs per minute. Choose a machine with the appropriate speed and efficiency to meet your production targets.

Accuracy and Precision: if precise measurement and filling are crucial for your product, consider machines with features like multi-head weighers or auger fillers. This is especially important for products with varying densities or weight requirements.

Flexibility and versatility: opt for a machine that offers flexibility in terms of handling different products and packaging formats. This is beneficial if you plan to diversify your product line in the future.

Ease of operation and changeover: choose a machine with a user-friendly interface and easy setup procedures. Quick changeover capabilities are also essential if you need to switch between different products or packaging formats frequently.

Integration with existing equipment: if you already have other equipment in your production line, ensure that the chosen vertical form fill seal machine can seamlessly integrate with existing machinery.

Space requirements: consider the available floor space in your production area. Choose a machine that fits within your space constraints without compromising on the machine efficiency and operator friendliness.

Maintenance and support: evaluate the maintenance requirements of the machine and check for the availability of technical support and spare parts. A reliable after-sales service is crucial for minimizing downtime.

Compliance with industry standards: ensure that VFFS machine complies with industry regulations and standards relevant to your product and market.

Budget considerations: define your budget constraints and choose a machine that meets your requirements without exceeding your financial limits.