Service Agreements

Find out more about our Service Agreements here.

The new, cost-efficient SVP Essential is a fully automated, ready-to-use system to produce simple parenterals such as analgesics, insulin, and generic drugs.

Learn more

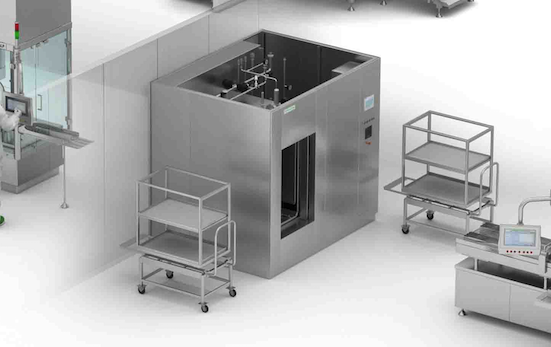

Syntegon’s portfolio of compact pharmaceutical cleaning systems for the low, medium and high output ranges prevents potentially harmful substances from compromising operator and patient safety.

Learn more

Thanks to a wide range of depyrogenation tunnels and related sterilization technologies, we provide versatile solutions for an effective and sustainable pre-treatment of liquids in open, semi-sealed or closed containers.

Learn more

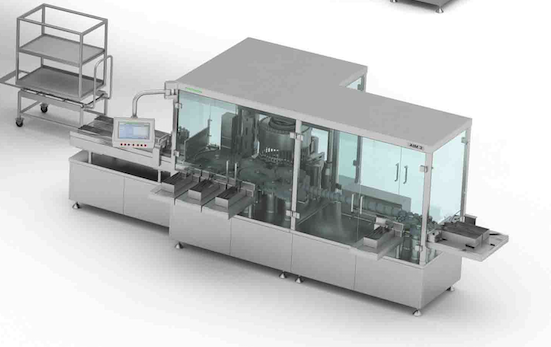

A wide range of technologies, including valve piston and peristaltic pump, mass-flow and time-pressure filling, make sure you can fill your products in a highly customized way. Tool-less format changes and filling stations with a variable number of filling heads increase the flexibility of your filling processes.

Learn more

Syntegon has established a comprehensive portfolio, including open RABS, closed RABS, containment and isolator systems.

Learn more

Versatile sterilization solutions for an effective treatment of porous loads and liquids in open, semi-sealed or closed containers.

Learn more

State-of-the-art technologies for visual inspection and container closure integrity testing (CCIT), including high voltage leak detection (HVLD), static division (SD) and headspace analysis (HSA).

Learn moreLiquid pharmaceuticals, their containers and process equipment all require reliable sterilization to ensure maximum pharmaceutical safety. We offer you the ideal portfolio: the Syntegon subsidiary SBM provides versatile autoclaves for an effective treatment of porous loads and liquids in open, semi-sealed or closed containers such as vials, ampoules, and cartridges. Be it vacuum-steam, steam/air mixture, or hot water shower process – we will support you in selecting the ideal sterilization method and achieving reproducible processes while optimizing your energy requirements.

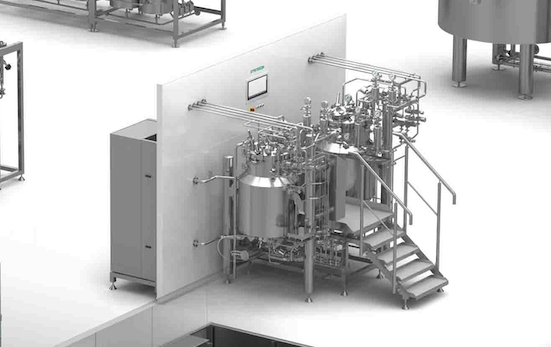

When it comes to bioprocessing, the systems from Syntegon’s subsidiary Pharmatec flexibly support the production of small and large volume parenterals (SVP/LVP) and infusions (IV). The process solutions comprise modular set-ups of temperature-controlled stainless-steel tanks that can be assembled to meet customer-specific settings. The new, cost-efficient SVP Essential is a fully automated, ready-to-use system to produce simple parenterals such as analgesics, insulin, and generic drugs.

Before and after filling, vials, ampoules, syringes, and cartridges need to undergo a crucial process step. Thorough internal and external cleaning is necessary to remove product residues and other contaminants from the containers’ inner and outer sides. As such, cleaning prevents potentially harmful substances from compromising operator and patient safety. Syntegon’s portfolio of compact pharmaceutical cleaning systems for the low, medium and high output ranges support manufacturers in reaching this goal. The hygienic and ergonomically designed solutions allow to clean a wide variety of containers, with special emphasis on fast and easy operations.

Whether you are filling liquid pharmaceuticals into ampoules, vials, injection and infusion bottles, cartridges or syringes: the reliable pre-treatment of containers significantly contributes to product safety. Thanks to a wide range of depyrogenation tunnels and related sterilization technologies, we provide versatile solutions for an effective and sustainable pre-treatment of liquids in open, semi-sealed or closed containers. Dry heat, vacuum, steam/air mixture and hot water shower sterilization help you achieve reproducible treatment quality while optimizing your energy requirements.

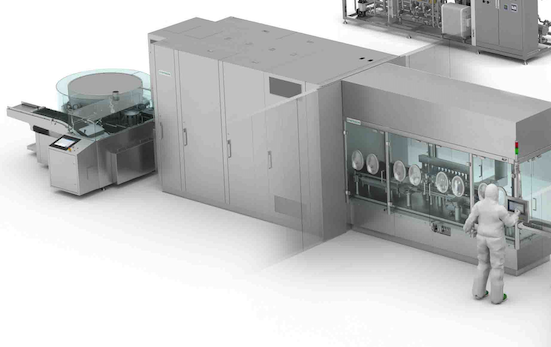

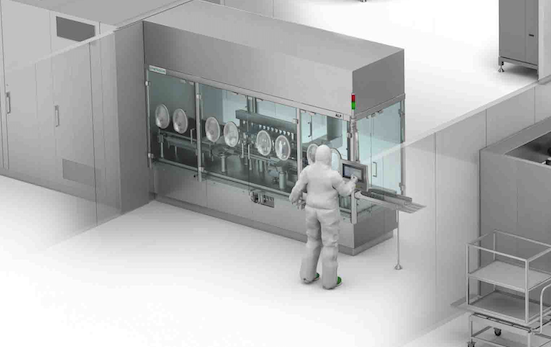

Our filling systems for pre-sterilized packaging combine flexibility and precision: a wide range of technologies, including valve piston and peristaltic pump, mass-flow and time-pressure filling, make sure you can fill your products in a highly customized way. Tool-less format changes and filling stations with a variable number of filling heads increase the flexibility of your filling processes. Subsequent sealing is equally versatile, offering you a variety of methods such as gas burning or vacuum stopper insertion for tightly sealed containers. In-process control (IPC) further improves filling quality with constant checks of filling weight and stopper location.

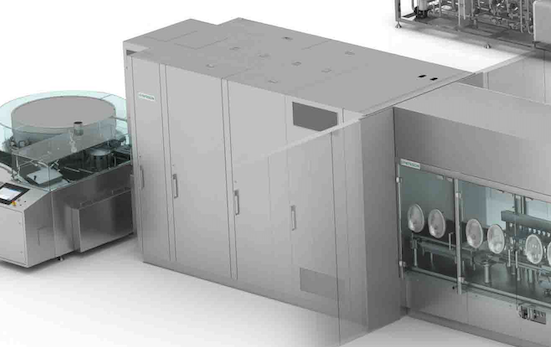

Aseptic filling is all about product safety – and thus the separation of operators and pharmaceutical ingredients. Isolator technology helps to build this crucial barrier. With over 40 years of US-based and 25 years of Europe-based experience in the design and manufacture of barrier systems, Syntegon has established a comprehensive portfolio, including open RABS, closed RABS, containment and isolator systems. We focus on each component to make sure it seamlessly interacts with others: safe interfaces between filling machines, isolators and subsequent systems, e.g., freeze-dryers or capping machines are a top priority.

The Syntegon company SBM (Schoeller-Bleckmann Medizintechnik) offers a vast portfolio of versatile sterilization solutions for an effective treatment of porous loads and liquids in open, semi-sealed or closed containers. The vacuum-steam, steam/air mixture and hot water shower processes support you in achieving reproducible equipment and terminal sterilization while optimizing your energy requirements.

Like any pharmaceutical container, ampoules require thorough inspection to ensure patient safety. Our wide range of manual, semi and fully automated inspection machines inspects liquid and lyophilized pharmaceuticals for particles and container defects. Thanks to our long-standing inspection expertise, we offer state-of-the-art technologies for visual inspection and container closure integrity testing (CCIT), including high voltage leak detection (HVLD), static division (SD) and headspace analysis (HSA). Moreover, Syntegon provides fully integrated inline inspection solutions for several inspection tasks such as defects detection and stopper seat inspection.

Find out more about our Service Agreements here.

Find out more about Digital Solutions here.

Find out more about Parts here.

Find out more about Maintenance here.

/remote-assistant.jpg?width=640&height=380&name=remote-assistant.jpg)

Find out more about Technical Support here.

Find out more about Modernizations here.

Find out more about our Training here.

Find out more about our Expert Services here.

Discover Syntegon, a leader in vaccine manufacturing equipment with over 30 years of experience and 200 successful projects worldwide.

Explore Syntegon's transition from Waiblingen to new locations, setting the stage for future growth...

Join us this June for our OSD Academy expert seminar “Granulation – from powder to tablet”.

Learn more about our sustainable coffee packaging solutions.

Join us at Pharmatag 2025 in Crailsheim, Germany, and experience how co-creation revolutionizes...